Hardware

Overview of the most common hardware on the rover!

Fasteners

Bolts

Bolts are fasteners with externally threaded shafts. They fasten onto a nut or female-threaded hole. Bolts we use are typically tightened with a hexagonally-shaped key.

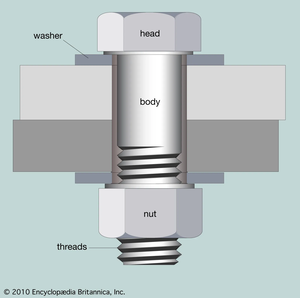

In this image, a bolt mates with a nut on the opposite side of the material to be fastened:

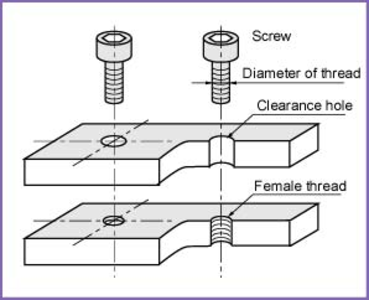

In this image, a bolt goes through a clearance hole (a hole that the bolt slips through) on one plate and mates with a tapped hole (a hole that has threads in it) on a second plate:

There are several important characteristics of bolts, including the system of measurement, naming, and head type.

- Metric vs Imperial: metric bolts use mm for dimensions, while imperial bolts use in for dimensions.

- Bolt sizing

- Metric:

nominal diameter-pitchxlength.- e.g. M4-0.7 x 12 is a bolt with a 4mm diameter, 0.7mm between threads, and 12mm of length

- Imperial:

major diameter-threads per inchxlength- e.g. 1/4-20 x 1/2" is a bolt with 1/4" diameter, 20 threads per inch, and 1/2" of length

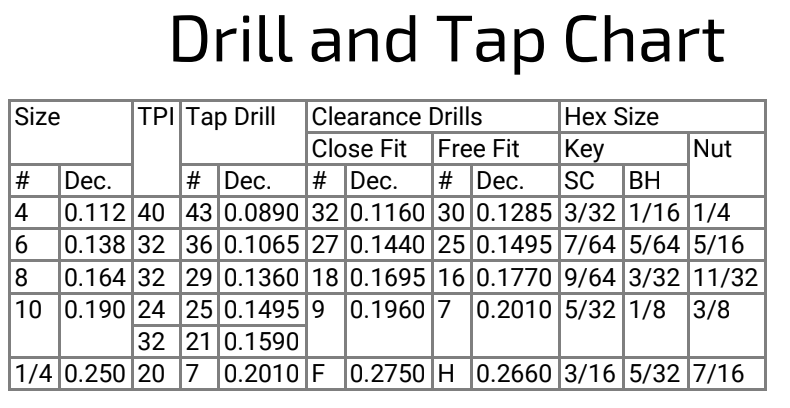

- As you work, you will begin to memorize these useful dimensions for imperial bolts:

- Metric:

Use imperial first. Only use metric if off-the-shelf items require them. The most common bolts we use are #10 and 1/4" bolts--these should cover 90% of your needs.

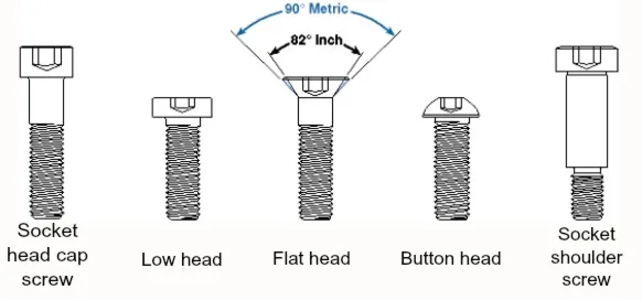

- Head Types:

- Button Head: Used for standard load applications.

- Socket Head: Used for high load applications. Taller head and bigger hex size allows for more torque to be applied when tightening, but requires more clearance.

- Flat Head (CounterSunk): Used when little clearance is available for a head. Requires countersink drill bit.

- Loctite

- Loctite threadlocker is a liquid or gluestick that you rub on the first few threads of the bolt before fastening onto a tapped hole (not on nuts). It then expands and solidifies to fill the gap between the threads, friction-locking the bolt in place.

- You should always use loctite on final assembly because screws can loosen and fall out due to vibration.

- When adding loctite, clean off any old loctite (white crust) before reapplying to ensure the new loctite has clean threads to tighten.

- In almost all cases, use blue loctite.

Do not use loctite for any bolt that fastens through plastic--the fumes released may crack/weaken the plastic. Use super glue instead if necessary.

Advanced Topics

- Coarse threads vs fine threads: In the imperial system, every bolt diameter has a coarse and a fine threaded version (UNC vs UNF) that indicates the relative threads per inch

- For example, a #10 bolt has 10-24 (coarse) and 10-32 (fine) threading.

- Fine threads are more likely to be galled/cross-threaded and require more turns to fasten, but are stronger overall because there are more threads.

- Pros and Cons

- Imperial bolt size numbers follow this equation: 0.06" + (0.013 x number)

- Bolts should be preloaded (tightened a bit) because it actually lessens load on the bolt

- On structural joints, it's a rule that the bolt should break before the threads strip in the tapped hole. A rule of thumb to accomplish this is that the depth of a tapped hole should be 2x the nominal diameter of the bolt. For less or non-structural components, you can go down to 1x or 0.5x, just trust your gut

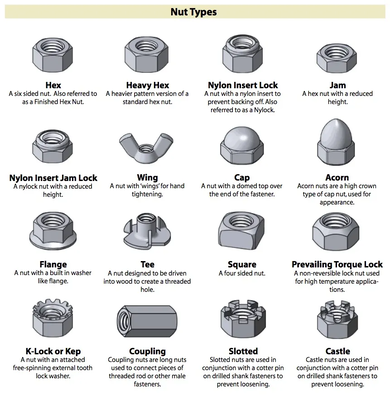

Nuts

Nuts are fastening elements used in conjunction with screws.

There are many different types of nuts for different applications. Some of these are listed:

- Hex Nuts: general purpose nut

- Lock Nuts: a nylon insert compresses when the bolt is fastened, "locking" the nut in place. most commonly used

- Flange Nuts: a flange distributes pressure, so you don't need a washer

- Wing Nuts: wings allow tightening and loosening by hand

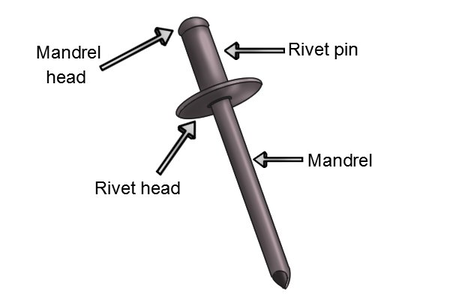

Rivets

Rivets are permanent fasteners that work by squeezing two items teogether by forcefully crushing metal. They are used when you can only access one side of the material, and are very easy to use with the right tools.

There are a couple important parts of a rivet:

- Rivet pin: important features are diameter and grip length. Grip length determines how thick the material that you are fastening together can be.

- Head: the head can be dome-headed (similar to button-headed bolts) or flush-headed (similar to flat-headed bolts)

Rivets aren't fully permanent--they can be "drilled out" and replaced using a drill bit that corresponds to the diameter of the rivet pin

The most common rivet we use is a 3/16" diameter rivet that fits into a 0.196" hole (hole size for #10 clearance). The hole is bigger because the rivet expands.

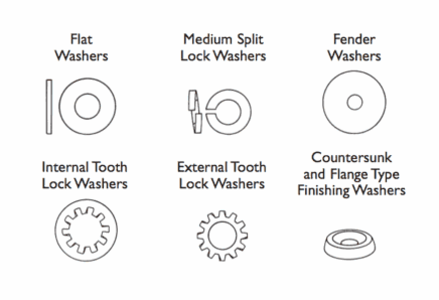

Washers

Washers are used to distribute the load of tightening a bolt over a wider area, allowing the bolt to be more strongly tightened without damage to the surface. Especially important for plastic.

There are many different kinds of washers that you can look up for more info--some are shown in the image below:

Flat washers, the most common washer, have a flat side and a rounded side--the flat side goes to the material and the rounded side goes to the bolt

Rotary Motion

Shafts and Spacers

Shafts are used everywhere for rotary transmission. The most common for our use are roundshafts and hex shafts.

Spacers are just cylinders that keep distance between two elements on a shaft. They're typically nylon plastic.

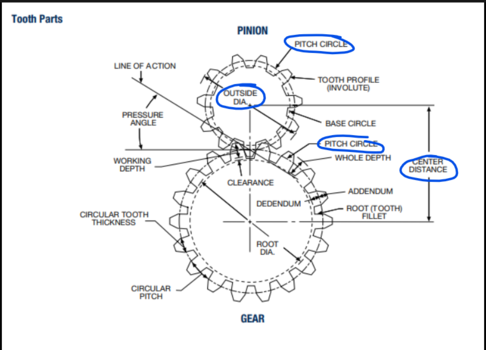

Gears

Gears are one of the most basic pieces of rotary transmission hardware. They are used to swap rotation direction and in gearboxes for reducing speed/increasing torque.

There are a few important characteristics about gears:

- Tooth Count: How many teeth there are, needed for gear ratios.

- Pitch Diameter: Important for designing gears to mesh. Essentially, if the pitch diameters of two gears are tangent to one another, then the gears will mesh properly.

- Outer Diameter: The diameter of the whole gear.

- Center Distance: The distance between the centers of the gears.

Avoid brass gears--they'll get chewed up. Use 7075 aluminum or steel gears.

Advanced Topics

Technically, the gear shown in the picture above is a spur gear. However, there are many other useful types of gears:

- Bevel Gears: Used for 90 deree rotational transmission. A bevel gear with a 1:1 ratio is called a miter gear.

- Worm Gears: While spur gears can cause a lot of backlash, worm gears are great for reducing backlash and smooth motion, as well as big gear reductions and quieter operation.

- Gear Racks (aka Rack and Pinion): Simple mechanism used to convert rotational motion to linear motion via gears.

- Helix and Herringbone Gears: Helical gears have teeth angled in a helix, resulting in more teeth contact and stronger power transmission, with side effect of some axial thrust force. Herringbone gears also have angled teeth, but they are shaped like a V so that the axial thrust forces cancel each other out. A Herringbone gear is a solid choice for 3D printed gears, as it gives more tooth contact and is quieter.

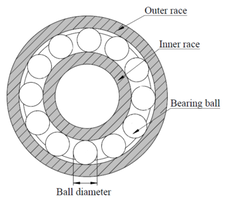

Bearings and Bushings

Bearings are commonly used to minimize the friction of a spinning shaft. An important feature of both bearings and bushing is whether or not they are flanged.

There are several different kinds of bearings that we've used commonly:

- Ball Bearings

- The shaft that spins goes in the middle and turns with the inner race.

- There are two important kinds of bearings: radial and flanged. Radial bearings have no flange and slip through holes. Flanged bearings have a flange on the outside so they can rest on a surface.

Bushings are similarly used to minimize friction but have no moving elements and are used for low speeds of rotation. They are simply a low-friction cylinder made by injecting lubricant into metal somehow.

Advanced Topics

- Needle Roller Bearings: Used where the shaft is too large and a ball bearing would get too big.

- Thrust Bearings: Used where two faces rotate against each other and support axial loads.

Lead Screws

Lead screws are essentially long bolts that are used to convert rotational motion to linear motion.

Advanced topics

(click links on certain key words for more info)

Some lead screws are back-driveable, i.e. when a linear force is applied, the nut will turn and move backwards. Other lead screws are not back-driveable because the friction force increases faster than the torque to turn. Because a lead screw is essentially an inclined plane, back-driveability is analagous to the angle of repose of an object on an inclined plane. Back-driveability is related to the helix and lead angle as well as the efficiency of the lead screw because efficiency is related to losses of friction.

Lead screws have several different types of thread profiles, and these affect strength, precision, and back-driveability.

Lead screws can have more than one start, meaning there are multiple individual threads running along the length of the shaft. More starts means more lead distance (distance traveled/revolution).

Ball screws are an alternative to lead screws that use actual balls (similar to ball bearings) to travel, decreasing friction and increasing back-driveability.

Retaining Rings and Shaft Collars

Retaining rings are a low-profile solution put on the end of a shaft to stop the shaft from falling out the other way.

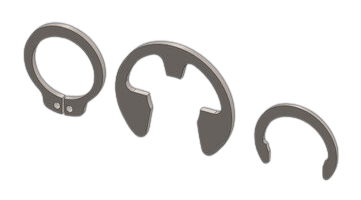

There are two most common kinds of retaining rings: snap rings and e-clips. They fit into a groove on the shaft of specified width and diameter.

Shaft Collars are a high-profile and strong clamp to stop the shaft from falling out. They commonly use bolts or set screws (a fully threaded screw with no head cap) to clamp.

Examples on the Rover!

Documented by Micah Hsu